With a storied history dating back to 1935, Yoshida & Co.continues to redefine craftsmanship and sustainability in the competitive world of bag manufacturing. President Yukihiro shares insights into their commitment to quality, sustainable practices, and the revolutionary Tanker Fiber, poised to reshape the industry.

Over the past decades, Japan has faced competition from regional rivals such as Korea, China, and Taiwan, who have adopted and replicated the Japanese monozukuri processes at lower labor costs. However, many Japanese brands, exemplified by companies like Uniqlo and Muji, have maintained their global leadership positions. In your opinion, what advantages do Japanese brands and manufacturers, including your company, possess within this competitive landscape?

Founded in 1935, our business was initially started by Yoshizo Yoshida, a bag craftsman who sewed each bag by hand, put them on a hand-drawn cart, and sold them himself. The founder's mission was clear – to preserve Japanese craftsmanship and the associated know-how. Since our establishment, this mission has become ingrained in the very DNA of our company.

Our daily interactions with craftsmen are not solely driven by a focus on maximizing business or increasing sales. Instead, our passion lies in the creation of high-quality, unique, and exclusive bags that no other brand can match. We, along with our craftsman partners, find satisfaction in producing products that users can enjoy for an extended period. This philosophy has been the cornerstone of our approach since the beginning and is a shared ethos among our manufacturing partners.

Japan is known for its aging population, with projections indicating that by 2050, the population will decline to below 100 million. This demographic shift raises concerns about labor shortages and a shrinking domestic market. To what extent are you exploring opportunities overseas to ensure the long-term success of your business?

From the inception of our business, our foundational philosophy has centered around preserving craftsmanship. This commitment has guided our collaborations both within and outside our organization, fostering partnerships that enable us to consistently produce high-quality bags.

Internally, we are dedicated to nurturing young craftsmen, cultivating them as valuable assets equipped to carry on our legacy. Our aspiration is to elevate the role of a craftsman to one that is esteemed within society, drawing inspiration from my observations in Italy, where craftsmen command respect and admiration.

In Italy, craftsmen are highly regarded members of society, and I aspire to cultivate a similar appreciation for the high-quality Yoshida bags and the craftsmen behind them. By raising awareness of our brand globally, we aim to have our craftsmen recognized for their exceptional skills and expertise. While we believe we have achieved sophistication in our technologies and the quality of our products, there remains a global shortage of such exceptional goods. Our aspiration is for more people worldwide to embrace and use high-quality products, contributing to the global appreciation of craftsmanship and quality.

While the domestic market may be contracting, it is crucial to recognize that it still holds substantial value and potential. I firmly believe that we produce unique bags that stand apart, not just within Japan but also on the global stage. Our pursuit of overseas expansion is driven not solely by the changing dynamics of the Japanese market but by a desire for global recognition. We are committed to showcasing the exceptional craftsmanship of artisans and expanding our customer base worldwide, ensuring a bright and sustainable future for our craftsmen and the legacy they uphold.

Many industry leaders emphasize the significance of partnerships, open innovation, and establishing relationships with local partners when entering international markets. You have demonstrated this approach through your development of the Tanker Fiber. What role does partnership play in your business model, and are you currently seeking new partners in overseas markets?

We recognize that we cannot accomplish everything independently, so our success is intrinsically tied to our partners. The strength of our partnerships goes beyond local knowledge, expertise, or reputation. What unites all our partners—whether in manufacturing, sales, or logistics—is a shared passion for Yoshida's bags. They are driven by a genuine love for our products such as PORTER and a desire to contribute to the creation of quality bags that stand the test of time.

The textile industry has one of the longest supply chains, which implies a lot of CO2 emissions, and coupled with the fast fashion phenomena, the textiles industry is one of the most polluting industries. The industry leads to an incredible amount of waste, with more than 10,000 clothing items filling landfills every five minutes as one of the examples. What steps are you taking to be more sustainable in your operation and have a more responsible and ecological production?

Our primary focus is not merely on expansion or profitability; it is centered on crafting high-quality bags that resonate with people and become cherished items in their lives. We have dedicated employees who pour their hearts into the manufacturing process, and we expect our partners to bring a similar level of passion and commitment to their respective roles. Our goal is to cultivate enduring partnerships built on mutual trust, ensuring that Yoshida's bags continue to be treasured and remembered by many for years to come.

What sets Yoshida bags apart from others? Could you elaborate on the manufacturing process of your bags and highlight the unique aspects that make them exclusive to Japan?

Rather than relying solely on public relations activities to convey the quality of our products, we believe in a more direct approach: allowing people to experience the difference for themselves. The most straightforward way for individuals to recognize the superiority of our bags is by using them and feeling the quality firsthand.

Each of the many bags we have introduced over the years and many of the designs that form the basis of these bags have withstood the test of time, with some lasting for over four decades. These standard products have undergone minor adjustments or refinements over the years.

Moreover, we offer repair services, and it's worth noting that the same craftsmen responsible for crafting our bags also handle repairs. This hands-on involvement in repairs allows them to identify areas for potential improvement and refinement.

Our craftsmen are never complacent; they continuously strive for excellence. They remain questioning attitude, continually learning, observing, and innovating to enhance the quality of our products. This commitment to continuous improvement is ingrained in our company's philosophy, a legacy passed down through generations. As a result, our products not only maintain their quality but often improve with time. It is this unwavering dedication to craftsmanship and quality that sets us apart and ensures that our products resonate with users for generations to come.

The textile industry, renowned for its lengthy supply chain, is associated with significant CO2 emissions. Paired with the fast fashion trend, it stands as one of the most polluting sectors globally, contributing to a staggering amount of waste, with over 10,000 pieces of clothing and bags discarded in landfills every 5 minutes. As a bag manufacturer committed to extending the lifespan of your products through repair services, what additional measures are you implementing to enhance sustainability in your operations and bolster ecological responsibility in your production processes?

In recent times, there has been a growing emphasis on social responsibility. Reflecting on our journey, we realize that our business practices have always been rooted in simplicity and sustainability. From our inception, we have upheld our founder's philosophy of "never wasting materials," which led to the natural act of repairing our customers' bags, and we have remained committed to the principle of minimizing waste. We have upheld a principle of minimal waste, reflecting our founder's ethos as a craftsman who deeply valued the products he created, in keeping with our teachings of "using things with care for a long time."

Our commitment extends beyond the finished products to the materials and components used in their creation. Unlike the fast-fashion industry, which often introduces new items each season, our goal is to produce items that endure. We prioritize longevity, continually refining our products to ensure they stand the test of time. This emphasis on durability is underscored by our robust research and development efforts.

We meticulously collect and repurpose leftover materials from the bag-making process. For instance, the coaster you see (Leather cup coasters are placed in front of the interviewer and President Yukihiro) is crafted from these residual materials, exemplifying our dedication to waste reduction and resourcefulness. At our core, we believe in cherishing every element of our craft and minimizing waste, aligning with our enduring commitment to sustainability and quality craftsmanship.

You have diversified your business across various brands, including Porter, Luggage Label, POTR, catering to a wide range of bag needs, from shoulder pouches to duffle bags and travel accessories. Among all your products, which brand or specific product do you believe holds the greatest growth potential?

All our brands exhibit substantial growth potential as we explore diverse applications and functionalities for our bags. In 1953, we introduced and revolutionized bag design by incorporating an expandable feature into the bag. PORTER was also the first company in the world to use Gore-Tex in bags. In recent years, we have also been the first in the world to use Cubic Eye Pike Lite, which is used in hospital beds and boasts high ventilation, ensuring air permeability and preventing moisture retention on the surface, as well as α-GEL, which has high shock absorption properties.

Another remarkable material in our repertoire is the Alpha Gel, employed to create soft handles, offering users the perception of comfort. Supplied by the Japanese company Taica, the Alpha Gel is utilized in our shoulder straps and handles for enhanced comfort. We continuously invest in research and development, resulting in patented features that enhance the user-friendliness of our products.

On the other hand, we have also innovation is the fragrance bag, designed to engage users' senses by emitting a pleasant scent, enriching their overall experience. These unique and yet new ideas for bags not only broaden the potential applications of our bags but also expand the addressable market, showcasing our commitment to continuous improvement and customer satisfaction.

You have developed Tanker Fiber, a 100% plant-derived nylon fiber derived from 60% castor oil plants and 40% corn. This innovation was designed to offer enhanced comfort, functionality, and environmental sustainability. Could you provide more details about the process of developing this unique bio-yarn, its distinctive properties, and how it compares to traditional petroleum-based nylon?

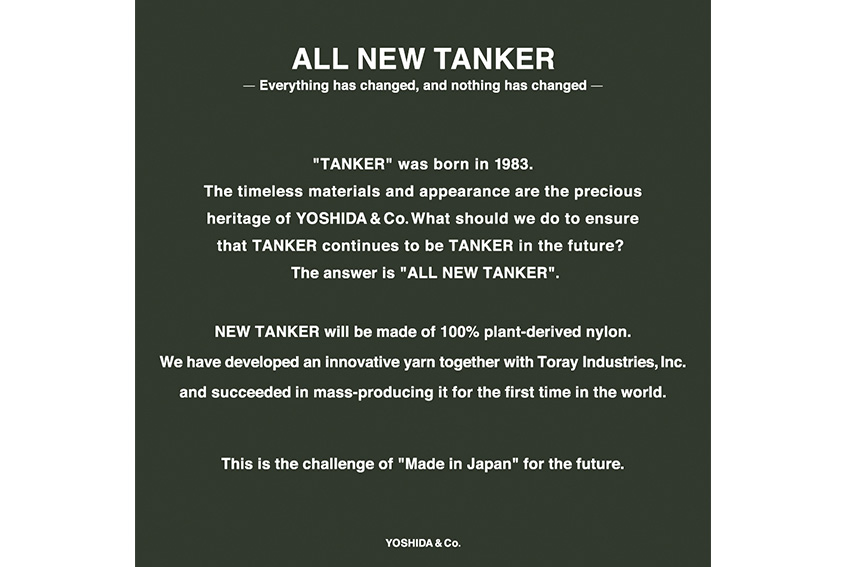

In our commitment to environmental sustainability, we sought a unique approach to address the issue of waste in society. Our exploration led to the development of 100% plant-derived nylon, a groundbreaking initiative achieved through collaboration with Toray. This innovative yarn, known for its strength and flexibility, has enabled mass production in collaboration with us, and we decided to use it in PORTER's signature series, "TANKER". Importantly, this breakthrough 100% plant-derived nylon material is not ours alone, but will be adopted by other companies as well.

Traditionally, nylon is derived from petroleum. However, our concept of creating 100% nylon from plants, coupled with mass production capabilities, presents a more eco-friendly alternative without compromising quality. Spearheaded by the enthusiasm of young talents, primarily individuals in their '20s and '30s within our company and Toray, this project was driven by a 28-year-old female team member. Not only working in the laboratory but also walking all over the production sites, she played a pivotal role in bringing this environmentally conscious product to mass production.

The significance of this project extends beyond the material itself. Toray's factory, where this innovative yarn is mass-produced, holds historical importance as the birthplace of nylon manufacturing in Japan. By leveraging shared technology and embracing the same spirit of challenge to preserve product quality, this project embodies a meaningful collaboration between our companies. Nylon is a synthetic material derived from crude oil and has been the standard for a long time. With the recent rise in concerns towards the environment and sustainability, products that are more crude oil-based are now being converted to be made from more eco-friendly materials. One of the steps we have taken is to use 100% plant-derived nylon.

Although recycling might sound eco-friendly, there is still a need to use oil-based materials. Also, in order to recycle, you need to use more energy, and therefore emit more CO2.

It is true that many companies have developed unique technology from recycled nylon, but we want to take a different approach. We had the fortunate opportunity to encounter Toray, and through that encounter, we have worked together to co-develop this plant-based material that is innate in the earth. We are in no way going against any current technology or current product; instead, we want to provide an alternative option through this 100% plant-based material.

Maintaining or exceeding the quality standards of traditional Tanker fabric is crucial for customer satisfaction. Are there any specific tests or quality control measures in place to validate that your plant-derived nylon meets durability, suppleness, and luster standards set by PORTER for your Tanker product?

This Tanker material has been developed by Toray and ourselves, and there are strict and stringent quality assurance standards at Toray. The new 100% plant-derived material surpasses these strict standards and is known to have heat and water resistance properties, which our material has equivalent capabilities and exceeds that. In addition to these characteristics, there are also lightweight properties as well as a softness that prevents skin abrasions. We conduct primary testing from different perspectives to cover the very basic properties. When we mass produce each batch, we do testing again and again.

Collaborating with Toray for material development necessitates effective communication and the seamless integration of expertise and knowledge. How has this collaboration influenced the innovation and success of the 100% plant-based nylon used in your Tanker?

This idea of producing nylon from 100% plants has been around for some time. We asked Toray if it would be possible to develop a 100% plant-derived fabric for bags that has stronger and more durable characteristics while retaining its supple properties. Toray said that while they were able to develop a thin yarn, creating a thicker yarn for use in bags would be much more difficult. We went back and forth with experimentation before finally reaching the goal.

In 2023, Tanker commemorated its 40th anniversary, but around the time Tanker launched, there were no existing nylon bags with a lifesaver jacket or flight jacket-type material inside. It was a very revolutionary product but at the same time, the pricing was quite high. It meant that in the beginning Tanker did not sell very well. Despite this, we had some core fans who supported Tanker. When reaching the 40th anniversary, we didn’t want to look back in time; rather, we wanted to create something that looked towards the future.

Even if a technology is revolutionary, if it is not explained well to customers it may not sell well. Educating consumers about the benefits of plant-derived nylon and dispelling any misconceptions is essential to allow the product to be successful in the years to come. How are you approaching consumer education as you shift away from traditional materials to more plant-based alternatives? When marketing the Tanker, how do you communicate the technical aspects of your 100% plant-derived material directly to consumers and how do you highlight the advantages?

Currently, we are planning our promotion of the new Tanker, but to be honest, we are not trying to push the sustainability of the material too strongly to consumers. As mentioned earlier, it is standard that nylon is oil-derived. The first step might be to let people know that nylon can also be developed using plant-based materials. From there we would gather interest in the new fabric.

The reason we are taking this approach is that we are bombarded with information on sustainability and the environment these days. It is a good sign that there is a rise in interest in environmental friendliness; however, it feels like there are always updates to the plenty of information out there related to sustainability. If we center our marketing around sustainability, there is a chance that our message gets lost.

Of course, we have exact data on how much CO2 we can cut by converting to these materials and how much we can contribute to a circular economy; however, we don’t want to stress this point in our PR activities. We want to rather surprise and delight people with the product itself.

In the next 10 years, we are going to see the prevalence of EVs and the new Shinkansen with the project starting over 50 years ago. I remember as a small boy hearing about cars that could float in the air using magnetic forces. I was moved and impressed by this innovation. When thinking about the 100% plant-derived nylon I reminisced about what I heard as a small boy. When you leave such a big impression or surprise on people, that memory remains in the hearts of those people for the rest of their lives. What we are pursuing is a concept to leave an impression on people rather than just following a sustainability trend, and interestingly, this is despite the fact that we have plenty of evidence to support our sustainability claims.

Do you foresee your new material being integrated into other products in the years to come?

At this moment, we have been informed by Toray that mass-producing the Tanker in mass quantities is very time-consuming, so at this point, we’ve reached maximum production capacity. My thoughts are that if Toray can produce in bigger quantities, and if there is a larger demand for plant-based materials, then the costs for this material will go down.

Are you intending to start sales in Japan first or are you planning on an overseas launch as well? What specific locations are you targeting?

In terms of sales, we will launch in Japan first in May 2024. From June 2024 onwards, we will start our overseas Tanker marketing. We actually exhibited our Tanker in January 2024 at Paris Fashion Week, and as a result, we have received orders from renowned department stores, buyers, and select shop owners. We are currently planning a year-long award tour for Tanker promotion in London, Paris, Berlin, New York, Milan, Hong Kong, Macao, Korea, and other places. This presents people with a chance to experience our products and see for themselves the quality.

I would like to talk about some of the hardships we felt during the development as well as some of the locations in which we produced the Tanker. First and foremost, the Tanker material is made 100% in Japan. Toray makes the thread, and then this thread is taken to Hokuriku to weave into a fabric. In Fukui Prefecture, there is a color dye company that assists us. All of the factories we work with have extensive history and tradition, therefore being open-minded in creating innovative products.

Creating the thread was an arduous process, and then on top of that were the weaving and dyeing processes too. Whenever there is an issue we reflect it on the potential cost and try to make improvements. This arduous process has actually led to the commercialization of the product. Toray’s plant-based material is weaved at one of Toray’s oldest domestic factories, and in 1951 this particular factory developed nylon for the first time in Japan. This new type of nylon was developed in collaboration with traditional craftsmen and young engineering mindsets. Based on all of Toray’s experiences, they were able to succeed.

With your plan to launch this material next spring, which products would you like to highlight for our readers that will feature this innovative fiber?

As we celebrate our 40th anniversary this year, we are thrilled to continue delivering our signature series that has become a source of joy for our customers. With a commitment to sustainability, we aspire to incorporate the newly developed 100% nylon fiber into our original series.

Due to the COVID-19 pandemic, numerous industries faced challenges. Physical stores, in particular, were significantly impacted due to shifts in lifestyle and consumer habits. Concurrently, online sales surged by approximately 13%, positioning Japan as the 4th largest e-commerce market globally. How did your business adapt to capitalize on this e-commerce growth?

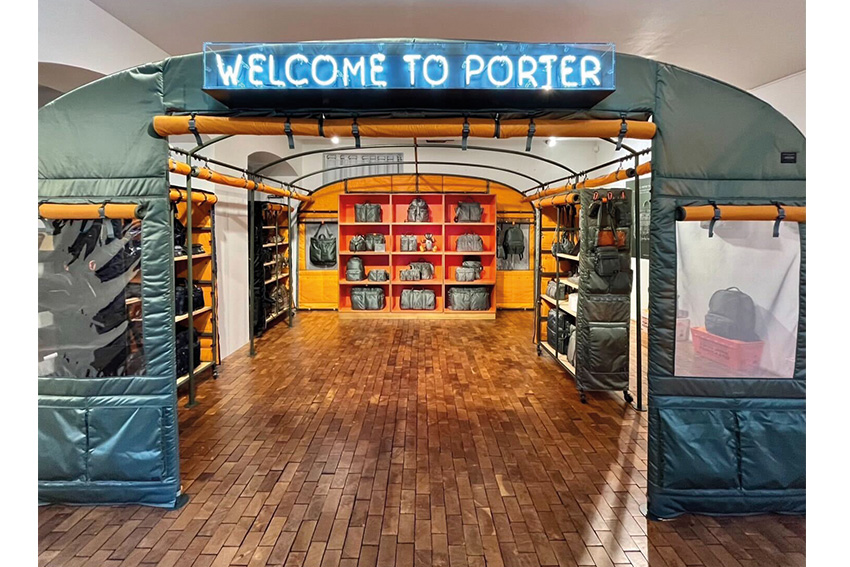

The COVID-19 pandemic presented unprecedented challenges for our business, especially with the temporary closures of our physical stores during critical periods in 2020. This situation compelled us to reconsider and adapt our strategies to ensure the well-being of our craftsmen and maintain a connection with our customers. While our initial focus was not on expanding e-commerce, we recognized the invaluable role of our physical retail stores in facilitating meaningful face-to-face interactions with our customers. This realization inspired us to enhance the quality of our offline services and explore innovative solutions such as opening temporary pop-up shops in remote areas to reach a broader audience. As a result of these efforts, we have successfully diversified our customer transactions across both offline and online channels, reinforcing our commitment to delivering exceptional service and fostering lasting relationships with our valued customers.

As the president of the company, which bag is your personal favorite, and which would you recommend to customers?

The Tanker series holds a deeply personal significance for me, as we share the same year of birth. Growing up alongside the Tanker series, I have witnessed its evolution and growth over the years, much like my own. Interacting with the craftsmen who are dedicated to manufacturing the Tanker series brings back cherished memories and strengthens my bond with this iconic collection. I vividly recall purchasing a Tanker bag with my own hard-earned money for an overseas trip, and to this day, that same bag remains an integral part of my life, evoking a myriad of memories and experiences. It is my earnest desire that our customers too forge lasting memories with our bags, cherishing them as timeless companions throughout their life journeys.

0 COMMENTS