Discover how JM is using innovative facility maintenance technologies to enhance building longevity, reduce life cycle costs, and decrease CO2 emissions.

How is JM best suited to tackle the challenges Japan’s aging population is having on facility management?

First, let me briefly introduce the company profile.

While it is true that we are a construction company we don’t build new buildings in a conventional sense, rather we act to manage existing buildings. We really are a different breed of company when you talk about the construction sector.

Contracts with us average around JPY 120,000 and currently we provide services to over 210,000 clients annually, and it is why we have embedded our company within lifecycle management activities and it means that we are capable of supplying these kinds of services to clients.

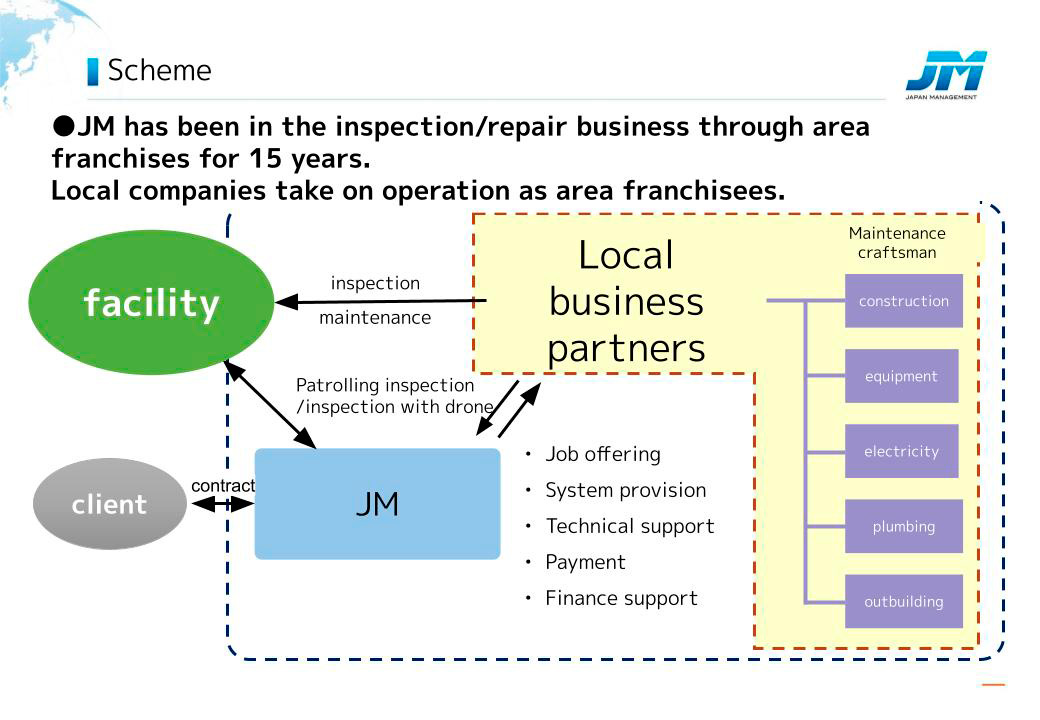

Back in 2011, there was the great Tohoku earthquake and at that time companies all across Japan started to think about reducing their CO2 emissions, solar panel and EV. We added solar panels to our portfolio, and clients such as Nissan have formed business alliances with us for things like plug-in chargers for EV. We were responsible for standardizing the manual for installing this charging facility. 4 years ago, we started a regional revitalization business to assist small towns with less than 100,000 population with low cost maintenance to their facilities. There are many towns beyond Tokyo and Osaka that need this kind of assistance. Small companies in these small towns also need ICT to realize low cost maintenance services. That is what we are aiming to achieve on a franchise basis offering services to local construction companies.

J is offering these maintenance services to some very big-name facilities, and our client portfolio also includes a number of public companies, municipalities, and prefectures. Our franchise model has a region of about 50 km, and what I mean by that is that we make sure to have one satellite office within a 50km radius of others in order to serve our customers that might have facilities all across Japan.

We have maintenance engineers who have expertise in construction, electricity, plumbing, and building equipment. Basically, imagine a situation where you run a franchise yourself and you need maintenance services standardized across all of your locations. This is where we can come in with our locations no more than 50km away from any one of those franchise facilities. We can deliver professional and prompt maintenance services to help assist companies that are looking for the kinds of services we deliver. Obviously, the franchise model isn’t the be-all and end-all of our business, and we have a number of other, diverse avenues that we are pursuing. One example is with our drone inspections that we run and another is our technical support. Essentially, we are taking all of these services and combining them under one umbrella.

Implementation system

To answer your question, I think an important aspect to discuss is what I am calling the “New Craftsmen Spirit.” What I mean by that is the importance of having craftsmen that are not afraid to utilize the latest ICT technologies as tools for the real-time management of facilities. Having these kinds of craftsmen is the pride of Japan Management. It is through this pride that clients come back to Japan Management time and time again for their maintenance services.

craftsman×ICT

In 2023 we now live in a world of digital tools. Everyone can have access to a wealth of tools such as phones and iPads and everything is accessible with just a few clicks. For facilities we manage we can provide 3D panoramic views, 3D designs, manuals, proposals, floor plans, and much more. Anything can be sent from a handheld device of a client or an employee. The heart of this service lies in our call center which we call our management center. Anyone that calls us is not only going to get the information they need but they can also gain some insight into what to do in a case of an emergency such as blackouts or earthquakes. Our call center operators can give prompt instructions on how things can be done in a proper way.

Getting back to answering your initial question, when compared to some general contractors, I think our company has a more individualistic approach and operators have more freedom. Our engineers will go any time of day, even when a shop is open. They are there to conduct maintenance to ensure facilities can function to the best ability they can, it isn’t any more complicated than that. When you think about the know-how needed to construct entirely new buildings and the know-how needed to maintain buildings they are actually complete opposites. While both are related to construction, our expertise lies in maintenance, and we try to accumulate as many maintenance officers as we can. More human resources mean more opportunities to promote our business expansion to customers. That is why we encourage flexibility and freedom with our operators, and I think is the defining factor on why we don’t have any issues with human resources at our company. They don’t feel pressure from upper management and they have the freedom necessary to apply their craft to the highest level possible. This attitude expands to the other franchisees we work with, and those companies share in our attitude and willingness to work.

Currently, we have 230 employees working with us directly and over 1300 working through our franchise model, meaning we have roughly 5000 maintenance services out in the field. We try to make our employees as happy as possible so that they can sustain the healthy businesses of our customers.

June 16th is actually an important date this year because it is when we hold our company-wide competition. Basically, it is just like the Olympic Games but instead of sports, it is for maintenance services. The winner receives a prize of JPY 1 million and we are looking for those that have exceptional skills.

JM Shokunin koshien

With this franchise scheme that you have ICT is essential to creating a standardized service and compensating for a lack of foreign workers. 5-10 years from now how do you anticipate digital tools will transform the services you offer to clients?

The key is going to be robotics, because as you know, humans get tired but robots can continue to work 24 hours a day, 7 days a week. With these kinds of robots, we can offer clients round-the-clock asset management and inspection services, allowing clients to visualize data of their production lines at any time. Maintenance can be easily analyzed and improved upon. The particular robot we are looking at right now is 1.8m high, but with this size, there are obviously spots it cannot reach so for that reason we are also looking into drone technology. You’ve seen Blade Runner, right? This is the level we are talking about. 5-10 years from now I believe we will be exiting the generation of iPhones and iPads and instead entering the era of more sophisticated technology.

Let’s take an example case of loose tiles at a construction site. The drone will be able to climb like a spider up to the loose tile and disperse glue, sticking the tile back in place. This can prevent all sorts of bad situations from happening at a construction site. Obviously, maintenance can be done by humans, there is no debate there however there are some risky situations where for the health of maintenance engineers, robots and drones are just better suited. Operators that are in high areas don’t always perform well whereas a drone that is allocated the same job could relay information clearly and precisely without risk.

inspection by drone

Are these drones and robots you’ve just mentioned still in the experimental/demonstration phase, or are they being used in your day-to-day operations?

We have already started providing these real-time maintenance services to our clients. The next device I would like to show is our 3D scanner. With this technology, some operators are able to go to actual construction sites and record data using their cell phones. Instantly a 3D is created in real-time using the software app. It can recreate small assets all the way up to entire production sites. The software is a modified version of Autodesk 3DSMax. Let’s take Starbucks as an example again, all you need to do is go in, ask to take a few pictures for maintenance, take the photos, sit in the back with a nice cup of coffee, and whilst you wait the app will create the 3D assets for you. Using that raw real-time data the operator can then make an estimate for the maintenance fee and submit it to the client. This system is still in the experimental phase and we haven’t fully implemented it for all clients, however, we have had a technical alliance with Autodesk since 2003.

3D Scanner

Next, I would like to talk about our BIM system. Konosu is a city in Saitama Prefecture with a population of 120,000, and there we have been utilizing BIM modeling. This form of 3D modeling can help with the bidding process because when construction services are required of general construction companies the contracts are bid on by a number of companies. It is easier to submit the winning bid if you provide 3D data to potential customers and that BIM technology allows us to collect big data inside. This 3D platform is very important to some smaller construction companies because they don’t tend to utilize ICT technologies very often but this system allows them to get acquainted with methods of the future. In many cases those contracts might go to a smaller, more regional firm than a large general constructor. BIM modeling is so vitally important when it comes to maintenance service as it really allows our operators to understand the makeup of a building and to understand where things such as piping and foundations are.

BIM model

This 3D scanning technology has been utilized in 7-11s to help with the maintenance services we provide this chain. We can identify the trouble using the data acquired during the 3D scan and using our software, engineers can be pointed in the right direction to manuals and information on resolving similar issues. That in-depth information proves crucial for the engineers and the pictures allow them to conduct their services swiftly and effectively. Essentially, we are looking for technology to simplify the work of our engineers and allow them to best apply their expertise.

Japan, especially in the construction field, has a reputation for being a bit slow to adopt new technologies. As a country, Japan routinely ranks low on the Global Digital Competitiveness Rankings, and I think this comes down to the country’s flexibility to use these kinds of tools. How can you convince local companies to adapt and adopt these digital technologies that may be out of their comfort zone?

Back in 2002, we started these services and it really wasn’t profitable. We had to spend more than our annual profit in order to afford these kinds of services, and to be honest, embedding new technologies is still a very costly endeavor. What we did to counter this was to invest in certain local businesses in order to expedite their use of newer technologies

At that time we had to invest a lot of money into our maintenance services and to be frank, those times weren’t easy. We even had to get acquainted with the technology and train our people properly. We then took that knowledge we acquired ourselves and introduced it to some local companies through our maintenance services. It was a long path and that initial investment was substantial, to say the least. Thankfully we were able to ride that wave to the end and here we sit as a successful business.

It can be a risky situation, and like many general contractors out there, should we fail to meet a project deadline it can be disastrous. With the model we have set up now, we are more or less safe from risk, but we still need to sustain the maintenance services we do provide. We are fortunate in the fact that maintenance is a necessity for almost any business out there eventually. That is why we need to maintain certain levels of technological know-how, in order to continue our business into the future, no matter what that future may hold.

Our main approach isn’t really a rapid income one, and we aren’t pursuing super high margins, rather the company’s focus is to provide and sustain maintenance for our clients at the highest level possible, thus achieving customer satisfaction. This approach requires investment, and I mean substantial investment. If you were to look at our financial statements year-on-year you will see that our profitability isn’t that high, but it is more or less enough for us to sustain this business. A big portion of those profits is reinvested back into the business so that we can escalate and keep up with the latest and greatest technological advancements in the field. It is very important to keep this up so that we don’t lose our customers.

How are you taking this business model and philosophy internationally? Your model is very much centered on finding partners and franchises to provide services locally. Are you interested in extending these kinds of partnerships or your franchise model to overseas markets?

Going to foreign markets is not new for us and we started applying our franchise business model in China back in 2012. It is working out well with the same approach we are having here in Japan. One of the biggest challenges facing us in China is that the ways that buildings are constructed there are different than here domestically. In many cases buildings do not stick to the original design, and in many cases, piping or walls might be totally different than the way it was supposed to be.

Another approach we are taking in China is actually in Shenzhen with a company called Vanke. Back in 2006 Vanke came to us and said that 40% of all residential areas in China were vulnerable to rainfall and leakages. Something needed to be done from a maintenance point of view, so this is where our firm can step in with our expertise. Since then our alliance with Vanke has been very successful.

Basically, we have taken two locations in China and applied 2 different business approaches. In Beijing, we have approached small, commercial locations such as 7-11, and in Shenzhen, we have taken a more residential approach to maintenance services. COVID-19 was a game changer in this sense because it caused damage to so many businesses, especially in China, with many firms deciding to withdraw from the country due to risks that were unseen suddenly becoming apparent.

Are you mostly focused on serving the needs of Japanese companies or Japan-based multinational companies in China, or are you interested in working with more Chinese companies or Chinese building managers? Additionally, are you interested in pursuing business in other neighboring countries as well as China?

Essentially, we are interested in cooperating with Chinese enterprises and Chinese building managers.

You also asked about potential future destinations for further expansion, and that is kind of a problematic point right now. The reason is that each country is different and has its own nuanced approach to business. We saw in China in the past that the way buildings are constructed is totally different from the way things are built in Japan, so in order to avoid these problems in the future we are utilizing internships. People from Bangladesh and South Africa are coming to Japan to train locally here with JM. They see how things are done here and then take that knowledge back to their home countries. Once they set up a platform of Japanese know-how we can use that as a foundation point for maintenance services and our franchise model.

Franchising in our minds is the only answer because even domestically we see the disparities between cities like Okinawa, Hokkaido, and Shizuoka for example. They are completely different natural habitats, yet all are Japanese cities. Each prefecture has its own specifics and when buildings are built they apply to local specifics. Nobody knows the region better than a franchise company that is located locally. This same approach will be taken with foreign countries.

Imagine that we come back in 4 years time and have this interview all over again. What goals or dreams do you have for Japan Management that you would like to have achieved by the time we come back for that new interview?

Frankly, many Japanese companies are looking to expand their businesses to developing countries like Southeast Asia for profitability and cost reasons. My approach is slightly different than most Japanese companies, and instead, I want to look for places that are in trouble and in need of assistance. We can go to those locations with our services and apply our best features. When the 2011 earthquake struck of the coast of Tohoku, we immediately rushed to the site to provide support without thinking about profits, and as a result, we unexpectedly made a profit. I would like to think of my business as one that helps those in need, basically sustaining the lifecycle of buildings and prolonging that lifecycle as long as possible. This is the philosophy of our company and it won’t change overseas. There are so many problematic regions in the world right now such as Russia, Ukraine, Africa, and the Middle East. Those places will need good maintenance services, so we would like to make our services available for those in need.

Additionally, I would like the company to be more proactive in the adoption of digital tools and technologies. Without these new tools, you cannot provide the best possible services you can. Sustaining our high-quality maintenance requires the use of the latest and greatest ICT tools. Autodesk has been vital in this respect, and we are really proud of our relationship with them. We would like to follow in Autodesk’s footsteps and globalize our franchise model on a worldwide stage.

0 COMMENTS