Explore the insightful interview with Akiyoshi Yoshimoto, President of Yoshimoto Sangyo Co., Ltd, as he delves into the challenges and opportunities faced by Japanese firms in the dynamic global industry. Discussing the unique advantages of Japanese companies amidst macroeconomic shifts, Yoshimoto provides a candid perspective on the impact of Japan's demographic challenges on his manufacturing firm. Discover the pioneering role played by Yoshimoto Sangyo in the artificial marble market, particularly the success of BMC material, and the development of the revolutionary Ultra Surface. Gain insights into the company's commitment to elevating housing conditions in Japan through the Fabbrica Yoshimoto brand, blending aesthetics and durability. Yoshimoto also shares his global expansion strategy, emphasizing the importance of understanding local needs and fostering partnerships. As he envisions a legacy of enhancing people's quality of life worldwide, this interview offers a glimpse into the innovative spirit driving Yoshimoto Sangyo's success.

We know that right now is a pivotal time for the Japanese industry. The past three years have seen severe supply chain disruptions due to COVID-19 as well as the US-China decoupling situation. As a result, corporate groups are looking to diversify their suppliers for reliability. Known for their reliability and advanced technology, Japanese firms are in an interesting position. Coupled with a weak JPY, observers argue that this is a very unique opportunity. Do you agree with this sentiment, and what are the advantages of Japanese firms in this current macro environment?

The current social, economic, and political situation may be viewed as favorable for the Japanese economy. For example, the depreciation of the JPY is contributing to an increase in the export of Japanese products. However, that is only in theory, and in reality, that is not happening. If this had happened before 1985 for example, Japan would have used this advantage to be proactive in exporting their products. However, historically speaking, Japan became too strong in the global market, and as a result of the Plaza Accord, the economic activities of Japanese companies were restricted by Western companies. That imposition to contain the Japanese economy damaged Japanese companies, and they have not yet been able to fully recover from the recession that they experienced due to the domestic and overseas situation. Economically speaking, the apparent success of major Japanese companies is primarily driven by high returns from overseas investments rather than substantial growth within the domestic market. Therefore, a careful approach is necessary when analyzing the Japanese economy.

One of the biggest challenges that Japan's economy is facing is Japan's shrinking demographic situation. It is the oldest society in the world with a rapidly shrinking population, and it is estimated that in the next 15 years, one-third of Japanese people will be over the age of 65. This creates problems such as a labor crisis. It is very difficult to find new younger talented graduates to replace the older more seasoned workers. It also creates a shrinking domestic market. What have been some of the challenges that this demographic shift has presented to your firm, and how have you been reacting to it?

The decline of the labor force in Japan is posing a great threat to us due to the shortage of manpower in our company, both in the office and the factory. To solve this issue, we are actively recruiting talented non-Japanese workers including the ladies here. Out of about 45 members of our company that work here, we have five members from Vietnam and one from Peru. Welcoming talented foreign workers is contributing to a new more efficient work style which has been good for our Japanese employees. As for the shrinkage of the domestic market, while we currently have the highest share in the artificial marble kitchen countertop business, there are still opportunities to increase this share and diversify our product lineup within the domestic market through various strategies. At the same time, our business is not confined to Japan, and we are actively seeking new sales opportunities overseas.

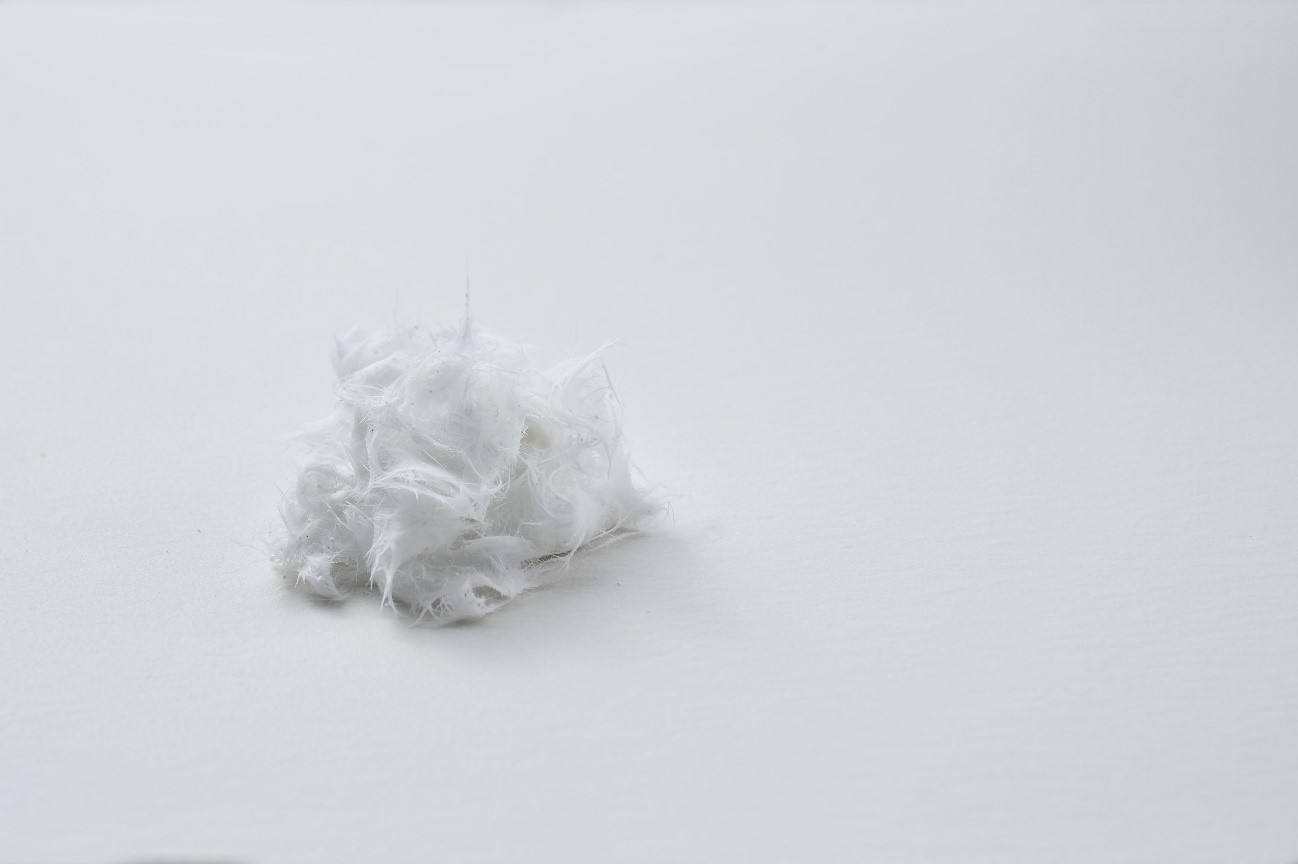

You just spoke about having a high share in the kitchen marble market. This dates back to 40 years ago when you developed technology to mass produce the BMC artificial marble material. Today, approximately 80% of artificial kitchens use BMC material. The development that you made allows for it to have a press-forming method that enables its mass production, and this has been crucial to its usage today. We are very curious to know about the advantages that this BMC material brings and why it has been so successful.

Image: BMC Artificial Marble material

Originally in 1947, with the development of forming technology for stainless steel, stainless steel became the mainstream material for kitchen countertops. However, in the 1970s, the concept of the kitchen system arrived in Japan from the West. With that came the American artificial marble. In 1989, we tried to develop and domestically produce high-quality artificial marble. It took us several years to develop and scale up mass production of our original BMC artificial marble. The unique characteristics of BMC are that it has high heat resistance and can also withstand chemical agents. Compared to other artificial marbles, it has higher impact resistance, making it very suitable for kitchen countertops, especially in Japan.

The system kitchen has been the mainstream of Japanese kitchen countertops. The sectional kitchen was another field with major companies such as Takara Standard, Cleanup, and LIXIL which at the time was called Sunwave Corporation. They were already dominant market players and they were looking for a material that could be easily distributed across Japan. They required a material with excellent material properties, high applicability, and high synchronicity with their kitchen designs. We then saw major companies adopting our material which allowed us to increase our market share and become a dominant player. To give you a precise figure, out of the total domestic kitchen countertops in Japan, around 63% are artificial marble, of which 80% use BMC. Out of the total number of kitchen countertops using various materials such as stainless steel and artificial marble, 50% are composed of BMC artificial marble.

We developed BMC artificial marble 40 years ago. Since then, some companies in the market were bought out by major companies to produce BMC artificial marble in-house. We currently have about 40% of the market share of BMC artificial marble kitchen countertops. This material is especially appropriate for the usage of around-water products such as vanity tops, and kitchen countertops as well as other applications.

One material that I was curious to ask you about is the Ultra Surface. It is a new material that you developed that utilizes special resin, fibers, and highly pure quartz. In addition to being scratch-resistant, like the BMC, it is also highly resistant to chemicals such as alcohol, alkaline, and bleach. What market needs did you identify in developing this product? What was the motivation behind developing the Ultra Surface in the first place?

Image: Ultra Surface kitchen countertop

The uniqueness of the Japanese market is that it is the major house manufacturers who decide what materials are used and not the individual purchaser. Working together closely with the manufacturers is very important, and we have been providing our BMC artificial marble to them for over 40 years now. Through our extensive business dealings with the major manufacturers, we received requests to give special functionalities to the existing types of artificial marble to make them more competitive in the market. At that time, countries such as Italy, Spain, and Israel had already produced quartz stones. We were one of the first to promote this material in Japan. Esthetically it was beautiful; however, there were negative aspects when it came to functionality. Therefore, we developed this special quartz-containing material Ultra Surface to overcome the negative aspects of quartz stones.

Quartz stones are equivalent to engineered stones. However, in Japan, quartz is better received so it is called quartz stone. The downside of quartz stone is that while it has a high hardness, it is easily scratched, and therefore does not have the desired longevity. Manufacturers and constructors are aware of the downsides but still prefer to use it for aesthetic reasons. However, from the point of view of the end users, it is not appropriate for their daily use on kitchen countertops, and there were some complaints as a result.

We developed our Ultra Surface to compensate for the downsides of the quartz stone, especially regarding its functionality. Ultra Surface is a well-balanced material with a hardness slightly less than quartz stone, but it is still hard enough to withstand daily usage. Also, since it is not easy to scratch, it can come in darker colors. We have a wide range of color variations. It can also withstand heat and chemicals. This functionality has been a positive for the house manufacturers. At the same time, it is also easy to process as it does not require a special machine like a water jet. Conventional artificial marble processing machines can be used by adding a coolant. Another advantage is that it has less risk of damage, so it is easy to carry and distribute. Our Ultra Surface material has been very well received by kitchen manufacturers and is used mainly for kitchen countertops.

Image: Ultra Surface colors

Is it a material that you have patented? Is there anything similar to this in the worldwide market or is it unique to the domestic Japanese market?

We do not register patents as once we register, we have to share information and disclose our recipes. We prefer to keep it as a hidden compound material of our company. Our production line is kept closed, and we do not even share it with our important customers.

In addition to your BMC products and Ultra Surface, in 2018, you released your original brand, Fabbrica Yoshimoto which offers various product designs used in homes for kitchens and washrooms and is a combination of high design and durability. What are the strategies you are employing to ensure the successful growth of the Fabbrica Yoshimoto brand?

I have been continuously researching the overseas market for 43 years. In the early years, I visited the US several times, and I was astonished to see the massive American homes. I thought that we could not compare them with Japanese homes. However, when I visited Europe, I was so amazed by how much the Europeans valued their homes and the higher quality of life they had in them. Although restricted in the size of its landmass, Japan had not yet properly maximized its housing. When I visited Italy, I was invited to the homes of CEOs and others. It made me realize how uncomfortable Japanese homes and lifestyles in the homes were. It became our company mission to contribute to the elevation of the housing conditions in Japan.

At that time, we had successfully developed BMC artificial marble, which improved the usability of artificial marble for kitchen countertops and vanity tops in bathrooms, which we refer to as around-water product areas. Using the technology and know-how that we accumulated over the years, we launched our Fabbrica Yoshimoto to offer a comprehensive solution to the living space by providing a comfortable environment.

In the years 2016 and 2017, we created the concept of Fabbrica Yoshimoto. Before its launch, we were an OEM manufacturer for housing equipment manufacturers. However, we planned, developed, and produced Fabbrica Yoshimoto by ourselves. Through this experience, we increased our sensitivity toward aesthetics by incorporating European ideas and developing in-house technology. This allowed us to retain our production scheme. We did not want to categorize ourselves as simply a supplier to major manufacturers. It was very important for us to have our original brand and this led to the launch of Fabbrica Yoshimoto. However, to avoid confusion, we are not trying to produce and offer a complete set of products like housing equipment manufacturers. This approach will continue to be our strategy in the future.

Image: Fabbrica Yoshimoto kitchen

You spoke about your experience visiting Europe in the early years and seeing the comparison between the Japanese market and the European market, and to your surprise, the European standard was much more elevated. Is that because in Japan there is a policy of scrap-and-build when it comes to homes? Japanese people generally love a new home, and the second-hand home market is not like it is in Europe where houses are built to last for 60, 70, or 80 years, and have three or four owners during that period. Is this the reason behind the lack of care when it came to creating kitchen systems? People were going to build a new one anyway, so they did not care about the quality. What is your view on that reasoning?

The scrap-and-build mindset of Japanese construction indeed was one of the reasons why I was shocked to see the comparison with European houses. In the majority of European cities, new builds are restricted by regulations. Therefore, the renovation of the interiors of existing buildings is more common. The idea is that the house is an asset that needs to be passed on, so it is only the interior that is renewed by each generation. In the US, the housing concept differs in the western and eastern areas, but people renovate their homes before moving into a new home to increase the value of the asset. However, in Japan, there is a scrap-and-build policy usually in cycles of 24 years in which the buildings are renewed. If you go to areas such as Shiga beyond Kyoto, you can see very small old-fashioned matchbox houses. Traditionally these types of small square houses were the living space of the Japanese. When I compared these houses to the traditional brick houses in Europe, I was shocked at the difference in the living standards in the houses.

The increase in internet access has allowed people to learn and make decisions on which kinds of materials or elements they would like to incorporate into their houses. I am not in the position to say this; however, this may have had an impact on major Japanese house manufacturers who often create standardized houses. Times have changed in Japan, and end-users are more actively seeking new alternatives for their homes. For example, there are showrooms in Osaka and Tokyo for imported curtains and other types of wallpaper, where the end users visit to make decisions on which ones they prefer. While it remains challenging, many Japanese house manufacturers are trying to provide more options for more high-end and more customized house production.

Some of the major companies that are more active in the field of the customization of houses are Mitsubishi Estate Residence, Sumitomo Forestry, and Asahi Kasei with Hebel Haus. These are some of the industry leaders. However, many other companies in the industry are not yet able to do so. There are also now more options for bathrooms. Conventionally the price was around JPY 300,000. However, the price can now range up to JPY 1 million.

You have been to Europe and you have taken these European ideas and established them in Japanese homes. We know that today you have supply partners in Spain, Germany, and Italy. You also have partners in Vietnam as well that can distribute your products. Are you looking to find more international partners to increase your network, as someone who is looking to expand your business overseas, what regions around the world do you believe hold the most potential for Yoshimoto Sangyo?

Different markets have different ideas when it comes to functionality and quality. For example, we want to target the European countries. However, they place more value on aesthetics and this can be seen through our imports from Spain and Italy. We are very careful with the materials that we import as we must determine if they are of adequate quality and have the required functionality for the Japanese market. For example, a European brand offers a sink that is very popular due to its aesthetics. Thirty years ago, I became a monitor of that sink, but functionally, it does not work well for daily usage. Within two years of use, the color stains were so severe that the white was no longer white and the bottom was a brown color. This kind of quality is not acceptable in Japan. We developed products that are both aesthetically and functionally suitable for the Japanese market. They were also well-received in Vietnam and China.

When it comes to our overseas strategy, it is difficult to directly enter the European market due to the different mindsets. Aesthetics is prioritized more than quality and functionality. Also, as a Japanese manufacturer, it isn't easy to penetrate European life. Our strategy is to first establish a strong foothold in the Asian market and be highly recognized for the quality and functionality of our products. We can then focus on expanding globally.

To do so, are you looking for local partnerships for sales or product development in those areas?

Our products cannot be delivered as a material itself or even in the form of countertops. It has to be appropriate to the Vietnamese lifestyle, so working closely with local kitchen manufacturers who share the same values is very important. Partnering up and understanding local needs is the key step moving forward. As it takes time to do so, our overseas expansion will be done step by step.

If we were to interview you on the last day of your presidency, whatever that may be, what legacy would you like to leave? What would you like your employees and colleagues to consider as the hallmark of your presidency? What would you like to be known for?

My philosophy is to uplift people's quality of life through living space. I want to use our materials and technology to help provide people with comfortable around-water products in their homes. This is not only the case for Japan but also across the globe from Asia to the Middle East, Africa, Europe, and the US. Finding partners who share the same mindset and passion as we do is something that I want to continue to pursue during my career. That is my goal for the future.

0 COMMENTS